€5.99*

No longer available

• Tinner

• 15 g Lead Free Tin

• Clean and tinning of soldering tips

Application

The hot soldering tip is tripped on the surface of the regeneration paste. The soldering tips regain their ability of moisturing. The durability of life can be extended significantly.

Empfehlung: Löten Draht

Available

• Nozzle bore Ø 0.6 mm

No longer available

• Nozzle bore Ø 0.8 mm

No longer available

• Length: ca. 1,6 m (Spool)

• Temperature Range: 350 – 450°C

Content: 1.6 metre(s) (€0.74* / 1 metre(s))

No longer available

• Length: ca. 1,6 m (Spool)

• Temperature Range: 350 – 450°C

Content: 1.6 metre(s) (€1.49* / 1 metre(s))

No longer available

• Length: ca. 1,6 m (Spool)

• Temperature Range: 350 – 450°C

Content: 1.6 metre(s) (€1.49* / 1 metre(s))

No longer available

• Length: ca. 1,6 m (Spool)

• Temperature Range: 350 – 450°C

Content: 1.6 metre(s) (€2.24* / 1 metre(s))

No longer available

• Length: ca. 1,6 m (Spool)

• Temperature Range: 350 – 450°C

Content: 1.6 metre(s) (€0.74* / 1 metre(s))

No longer available

• DIN EN ISO 9453: Sn99Cu1(NiGe)

• DIN EN 61190: Fuji Patent

• 3,5% Flux Material

• Melting Range: 227°C eutectic

• Ø 0,25mm - Spool with 0,05 kg

Content: 0.05 kilogram(s) (€149.80* / 1 kilogram(s))

No longer available

• DIN EN ISO 9453: S-Sn96Ag3Cu1

• DIN EN 61190: Sn96Ag03Cu0,4

• 3,5% Flux Material

• Melting Range: 217 - 219 °C

• Ø 0,25mm - Spool with 0,1 kg

Content: 0.1 kilogram(s) (€359.90* / 1 kilogram(s))

No longer available

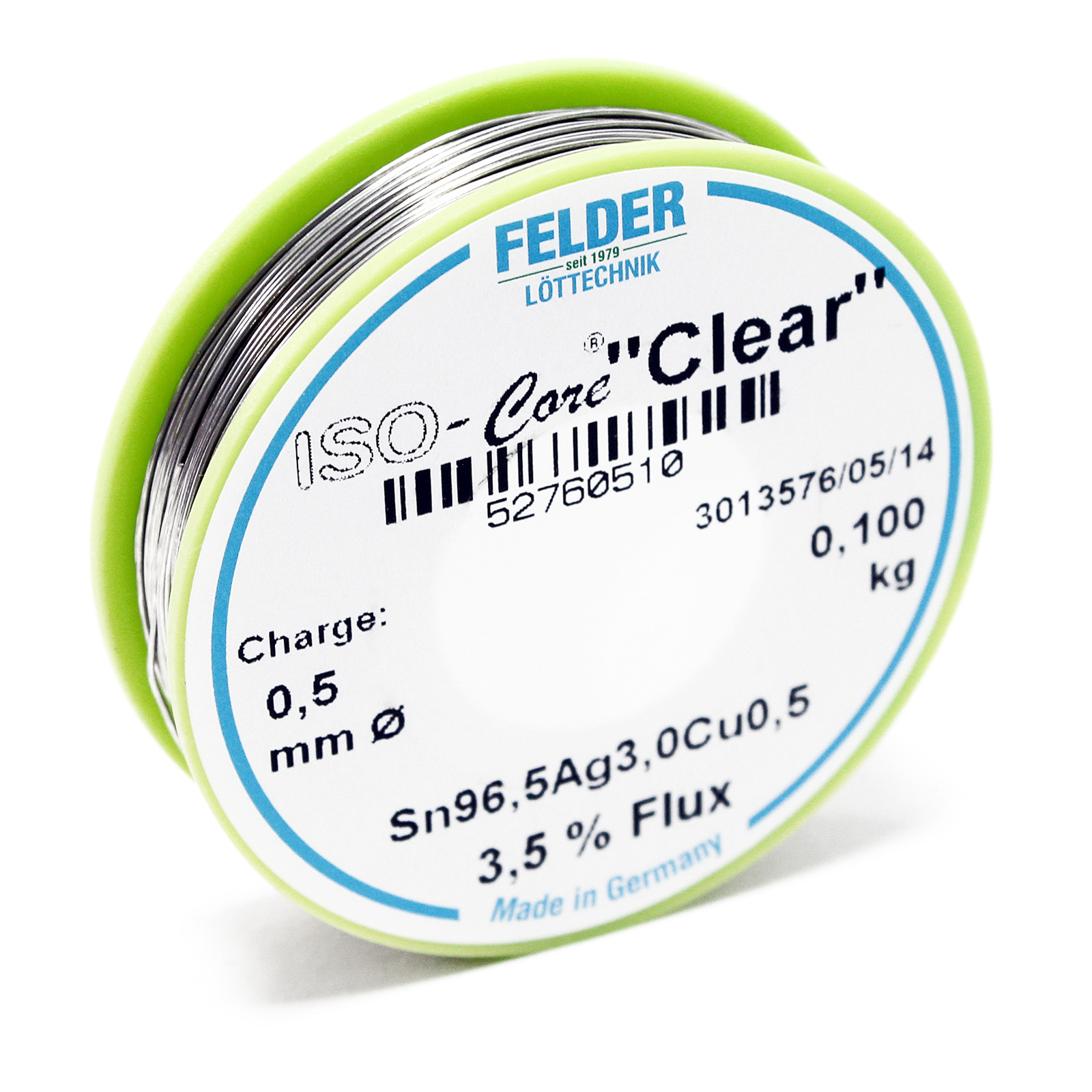

• DIN EN ISO 9453: S-Sn96Ag3Cu1

• DIN EN 61190: Sn96Ag03Cu0,4

• 3,5% Flux Material

• Melting Range: 217 - 219 °C

• Ø 0,5mm - Spool with 0,1 kg

Content: 0.1 kilogram(s) (€179.90* / 1 kilogram(s))

No longer available

• DIN EN ISO 9453: Sn99Cu1(NiGe)

• DIN EN 61190: Fuji Patent

• 3,5% Flux Material

• Melting Range: 227°C eutectic

• Ø 0,5mm - Spool with 0,1 kg

Content: 0.1 kilogram(s) (€109.90* / 1 kilogram(s))

No longer available

• DIN EN ISO 9453: S-Sn96Ag3Cu1

• DIN EN 61190: Sn96Ag03Cu0,4

• 3,5% Flux Material

• Melting Range: 217 - 219 °C

• Ø 0,5mm - Spool with 0,25 kg

Content: 0.25 kilogram(s) (€123.96* / 1 kilogram(s))

No longer available

• DIN EN ISO 9453: Sn99Cu1(NiGe)

• DIN EN 61190: Fuji Patent

• 3,5% Flux Material

• Melting Range: 227°C eutectic

• Ø 0,5mm - Spool with 0,25 kg

Content: 0.25 kilogram(s) (€91.96* / 1 kilogram(s))

No longer available

• DIN EN ISO 9453: S-Sn96Ag3Cu1

• DIN EN 61190: Sn96Ag03Cu0,4

• 3,5% Flux Material

• Melting Range: 217 - 219 °C

• Ø 1,0mm - Spool with 0,1 kg

Content: 0.1 kilogram(s) (€144.90* / 1 kilogram(s))

No longer available

• DIN EN ISO 9453: Sn99Cu1(NiGe)

• DIN EN 61190: Fuji Patent

• 3,5% Flux Material

• Melting Range: 227°C eutectic

• Ø 1,mm - Spool with 0,1 kg

Content: 0.1 kilogram(s) (€89.90* / 1 kilogram(s))

No longer available

• DIN EN ISO 9453: S-Sn96Ag3Cu1

• DIN EN 61190: Sn96Ag03Cu0,4

• 3,5% Flux Material

• Melting Range: 217 - 219 °C

• Ø 1,0mm - Spool with 0,25 kg

Content: 0.25 kilogram(s) (€139.96* / 1 kilogram(s))

No longer available

• DIN EN ISO 9453: Sn99Cu1(NiGe)

• DIN EN 61190: Fuji Patent

• 3,5% Flux Material

• Melting Range: 227°C eutectic

• Ø 1,0mm - Spool with 0,25 kg

Content: 0.25 kilogram(s) (€95.96* / 1 kilogram(s))

No longer available

• 15 g Lead Free Tin

• Clean and tinning of soldering tips

Content: 0.015 kilogram(s) (€399.33* / 1 kilogram(s))

Empfehlung: Löten Lötstationen

Available

• Soldering irons with ceramic heater

• Temperature range 300°C - 480°C

• Power consumption 35 W

No longer available

• Equipment for

• AOYUE Int738+

No longer available

• temperature area 100 - 480°C

• metal core heating element

• max. air flow 30 l/min

No longer available

• Temperature- and Airflow adjustable via button

• Soldering Iron with Fume Extraction

No longer available

• Temperature and Airflow adjustable via button

• 4in1: Desoldering, Soldering, Hot Air & Fume Extraction

No longer available

• Temperature control over control dial

• Digital display of actual and set temperature

No longer available

• Temperature adjustable via dial

No longer available

• Temperature via dial, indicated via display

No longer available

• 3in1: Desoldering Gun, Soldering Iron, Fume extraction

• Temperature and Airflow adjustable via dial, indicated via display

No longer available

• CPU controlled, temperature- and air flow control over control dial

• Temperature- and air flow display

No longer available

• Metallkernheizelement

• CPU geregelt, Temperatur- und Lufstromregelung über Taster

• Temperatur- und Luftstromanzeige

No longer available

• Metal core heating element

• CPU controlled

• Temperature and air flow control via buttons

• Temperature and air flow display

• Vacuum component lifter

No longer available

• Quartz IR heating element

• operable temperature range 80-450°C

No longer available

• Quartz IR heating element

• operable temperature range 50-400°C

No longer available

• Quartz Preheater 400 watts

• Soldering and Hot Air Station

No longer available

• Spring easy to clean

No longer available

• kurze Vorheizzeit, gleichmäßige Erwärmung der Platine

• da berührungsfrei, können auch Double-Sided Boards verarbeitet werden.

No longer available

• Temperature control over control dial

• Top Selling Soldering Station

No longer available

• Temperature control over control dial

• Digital display of actual and set temperature

No longer available

• Soldering irons with ceramic heater

• Temperature range 200°C - 480°C

• Power consumption 60 W

• Output voltage 24 V

No longer available

• Display, temperature and air flow adjustment via button

• Temperature of soldering iron via rotary knob

• Solder fume extraction

• Auto cooling function

No longer available

• 3 in 1: Hot Air, Soldering Iron, Fume Extraction and extended accessories

• Temperature and airflow adjustable via button

• Temperature of soldering iron via control dial

No longer available

• Temperature adjustable via rotary knob

• Indication via display

• Integrated soldering fume extraction

No longer available

• Composite ceramic heater

• Temperature range 150°C - 400°C

• Voltage input 12 V

• Weight 0,5 kg

Empfehlung: Löten Zubehör

No longer available

No longer available

BGA Schablone für 4200G0 0.60 mm

No longer available

• 100mm -300mm

No longer available

BGA Schablone für 82801DBM 82801 DB 0.76 mm

No longer available

BGA Schablone für 82801FBM 0.60 mm

No longer available

BGA Schablone für 82801GBM 0.60 mm

No longer available

BGA Schablone für 82801HBM 0.60 mm

No longer available

No longer available

BGA Schablone für 915PM 915 GM 0.60 mm

No longer available

No longer available

No longer available

No longer available

No longer available

Available

• Active Carbon Filter

No longer available

No longer available

No longer available

No longer available

No longer available

No longer available

No longer available

No longer available

No longer available

![66980486bc8367091158eefa71fd3bd392d379d6_91125_gal AOYUE [1125] Hot Air Nozzle QFP 10x10 for Hot Air Soldering Station](https://www.aoyue.eu/media/51/1f/07/1619444074/66980486bc8367091158eefa71fd3bd392d379d6_91125_gal.jpg)

![6f5c10edc973e0c78fa17a5345141cd0f24f4581_91126_gal AOYUE [1126] Hot Air Nozzle QFB 14x14 for Hot Air Soldering Station](https://www.aoyue.eu/media/03/3d/5e/1619444083/6f5c10edc973e0c78fa17a5345141cd0f24f4581_91126_gal.jpg)

![cabb354d78fe5ed26b86060d697a4bffd3787d77_91127_gal AOYUE [1127] Hot Air Nozzle QFB 17.5x17.5 for Soldering Station](https://www.aoyue.eu/media/54/52/3c/1619444093/cabb354d78fe5ed26b86060d697a4bffd3787d77_91127_gal.jpg)

![e020eb7b76ab8eabe11f92d28ea87a6785476343_91128_gal AOYUE [1128] Hot Air Nozzle QFP 14x20 for Hot Air Soldering Station](https://www.aoyue.eu/media/c2/05/b8/1619444101/e020eb7b76ab8eabe11f92d28ea87a6785476343_91128_gal.jpg)

![f0a97647ae3137f817bedf3999c82bc667237ab0_91132_gal AOYUE [1132] Hot Air Nozzle SOP 5.6x13 for Hot Air Soldering Station](https://www.aoyue.eu/media/18/05/08/1619444112/f0a97647ae3137f817bedf3999c82bc667237ab0_91132_gal.jpg)

![c794bf40e063e2095508e6de3bfe709fbe7e5821_91133_gal AOYUE [1133] Hot Air Nozzle SOP 7.2 for Hot Air Soldering Station](https://www.aoyue.eu/media/b1/ab/46/1619444127/c794bf40e063e2095508e6de3bfe709fbe7e5821_91133_gal.jpg)

![2d1f5afb6f6d40d9d304926b11903d0bff28a10d_91134_gal AOYUE [1134] Hot Air Nozzle SOP 7.2 for Hot Air Soldering Station](https://www.aoyue.eu/media/89/0a/70/1619444132/2d1f5afb6f6d40d9d304926b11903d0bff28a10d_91134_gal.jpg)

![42e7e048820ae1d3363e9ed60ee9c28fa4567537_91135_gal AOYUE [1135] Hot Air Nozzle 18.5 for Hot Air Soldering Station](https://www.aoyue.eu/media/1d/bf/59/1619444142/42e7e048820ae1d3363e9ed60ee9c28fa4567537_91135_gal.jpg)